Kit ma ki yubu kwede valve ni weko tic pa valve ni bedo maber, kit ma ki keto kwede ki kit ma ki geno kwede i yub me paip.TWSwabinyamo lok manok i kom kit me kubbe ma rwate ki kit ma gi tye kwede i pwony man.

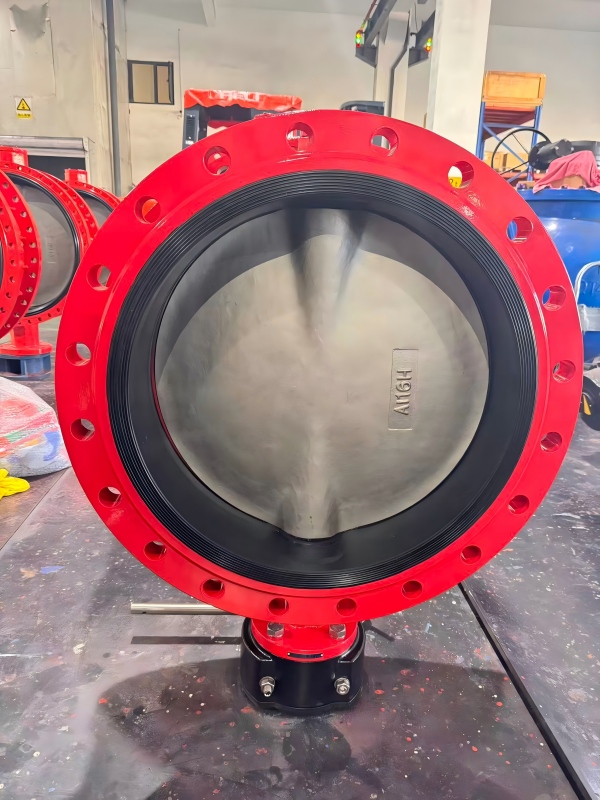

I. Kubbe ma ki keto i dul ma ki lwongo ni Flanged

Kit me kubu jami weny ni weko ki keto jami ma ki lwongo ni bolted ma ki keto i kom jami ma ki keto kacel.

Kit me umu ma pol:

-Kom ma okati woko: Kit ma ki yubu kwede ma pol kare, ki kom ma ki umu ma okati woko 2-3mm, ma rwate ki rwom me yamo ma lac (PN10-PN25).

-Concave-convex surface: tic maber me umu, ber pi jami ma lyel ki jami ma kelo two.

-Groove surface: maber loyo me umu, ki tiyo kwede pi jami ma kelo peko ki jami ma tye ki teko madwong.

-Ring connection surface: Metal ring gasket, ma ki yubu pi tic ma tek ki lyeto ma malo. Ber ne: Genne me umu ki yot me kwanyo ne.

Peko ne: dit ki pek, wel ne lamal.

Gin ma ki lwongo ni valve ni tye ki yub ma pe ki dul kom, ma ki gwoko ki bolt mabor i kin dul kom pa paip. Jami ma pire tek tye iye gedo ma yot, gedo ma pek ne yot, ki wel cente ma mite. Ento, mito rwom me keto ne maber ki tek me gwoko ne. Kit ma ki yubu kwede ni ki tiyo kwede ibutterfly valveskineno valves.

III.Kubbe ma ki lwongo ni Threaded Connections

Kubu ma ki lwongo ni Threaded connection obedo yoo me kubu ma tiyo ki jami ma ki keto me mako jami ki twero kwanyo ne i cawa mo keken.

Ber pa umu: yubu jami mapol miyo wel cente me yubu ne bedo piny, ma en aye yoo acel ma wel ne yot me kubu ne.

Peko ne: Yot me gonyo i te yeng yeng ki peko, ki rwom me peko ma tye i tyen yat ni miyo teko ne bedo piny.

IV. Kubbe me welding

Gin ma ki genne ma rii pi naka.

-Kit: Butt welding: Teko ma malo, tek pa pii manok, ber pi tic ma tek.

-Plug-in welding connection: Yot me keto, ber pi paip ma tidi. Ber ne: Pe mol, pe twero yeng yeng.

Peko: 5. Peko me poko ne. Kit me kubu mukene: Kubu ma ki mako: Ki tiiyo kwede i gang tic me gwoko lengo wek obed yot me lwoko. Gin ma ki keto i cing: Ki tiiyo kwede i jami ma ki tiyo kwede ki jami ma tiyo ki pii.

Kabedo me yero:

1. Yer yoo ma lubu rwom me lyeto ki rwom me lyeto: rwom ma malo ki rwom me lyeto omyera ki weld onyo ki rwate ki ring.

2. Malube ki kit ma jami ni tye kwede: Pi jami ma twero kelo peko, welding onyo tenon-joint surfaces ki miiyo tam iye.

3. Tam i kom keto ki gwoko: Kwanyo jami ma ki keto i flange kare ki kare.

4. wel ki kabedo: Wafer ni ber ki yot.

V. Giko ne :

Kubbe maber obedo gin ma pire tek pi gwoko kuc ki tic pa paip. Nongo kony pa dano ma ryek ki lok ma mako pyem i kom wabutterfly valve, gin ma ki lwongo ni gate valve, kineno valves. RwateTWSme nongo lagam maber pi gin ma imito.

Cawa me cwalo: Nov-25-2025